POLSER, as one of the globally leading companies in composite building products continues to add new products that provide better solutions to design and durability problems. In this context DURADECK FRP/GRP deck panels, provides superior span possibilities with high load carrying capacity, ultimate corrosion resistance and aesthetical aspects, all at the same time.

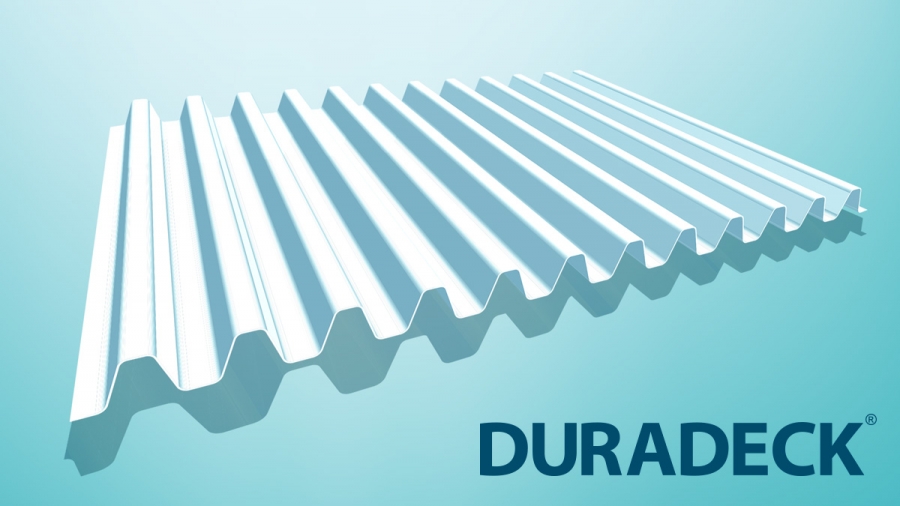

DURADECK is the trademark of POLSER which denotes FRP/GRP (Glass fiber reinforced plastic) deck panels that are produced on state of art continuous lamination production lines.

DURADECK FRP/GRP sheets are modern building products which have many different fields of application. They bring solutions to the projects where classical metal, fiber cement and asbestos based products are not ideal fits for the requirements. DURADECK panels could also be produced with fire retardant properties.

| Why use DURADECK? | Application Areas of DURADECK | ||

|

|

| TECHNICAL SPECIFICATIONS | |||||

| Properties | Test Method | Value / Tolerance | |||

| Physical | Profile code 0601-01 P8 (130/130) | POLSER | Dimensional tol. %10 | ||

| Thickness mm | Universal | 4 ± %10 | |||

| Surface properties Both face | POLSER | Top Surface ISO NPG Gel-coat (Optional) | |||

| Color RAL 1001 Beige | ISO 12647-2 | DE* ≤ 1,0 | |||

| Nominal weight | TS EN 1013 | 14 | kg/m² | corrugated | |

| Density g/cm³ | ISO 1183 | 1,6 - 1,7 | |||

| Water absorption % | ISO 62 | maks. 0,4 | |||

| Glass Fiber Content % | EN 1172 | min. 18 | |||

| Accustic attenuation factor, R'w | POLSER | 5 dB | |||

| Fire Resistance | BS 476 | Class 0 (Optional) | |||

| Max. Span | Universal | 4000 mm | |||

| UV Resıstance |

ASTM G154 cycle2 QUVB 313 lamp irradiance 0,71 Wm² 60°C 4h, condensation 50°C 4h |

EN ISO 16474-3 |

At the end of 1000 hours of test ∆E must be lower than ∆E ≤ 20 |

||

| Thermal | Thermal Conductivity W/mK° | DIN 51046 | 0,224 | ||

| Coefficient of Thermal Expansion (m/m/°C) | DIN 53752 | 30 x 10-6 | |||

| Term Service Temperature °C | Universal | ─ 40 + 120 | |||

| Mechanical | Tensile strength Mpa | EN 527 | 90 - 120 | ||

| Tensile Modulus of Elasticity, Mpa | EN 527 | 3000 - 5000 | |||

| Tensile Elongation at break, % | EN 527 | 1,25 - 2,5 | |||

| Flexural Strength, Mpa | EN 178 | 100 - 140 | |||

| Flexural Modulus, Mpa | EN 178 | 5000 - 8000 | |||

| Barcol Hardness | EN 59 | 40 - 55 | |||

| Chemical resistance | Acetic Acid %5, 25°C | Hydrochloric acid, %10, 30°C | |||

| Nitric acid %10, 30°C | Sulfuric Acid %30, 50°C | ||||

| Ethyl alcohol %25, 25°C | See Water, 40°C | ||||

| Sodium chloride water solution, 40°C | Chlorine, Gas, 50°C | ||||

| Silicone Oil, 55°C | Benzoic Acid saturated water solution, 40°C | ||||

| Carbon monoxide, Gas 55°C | Stearic Acid, 40°C | ||||

| ACCESSORIES | |

|

|