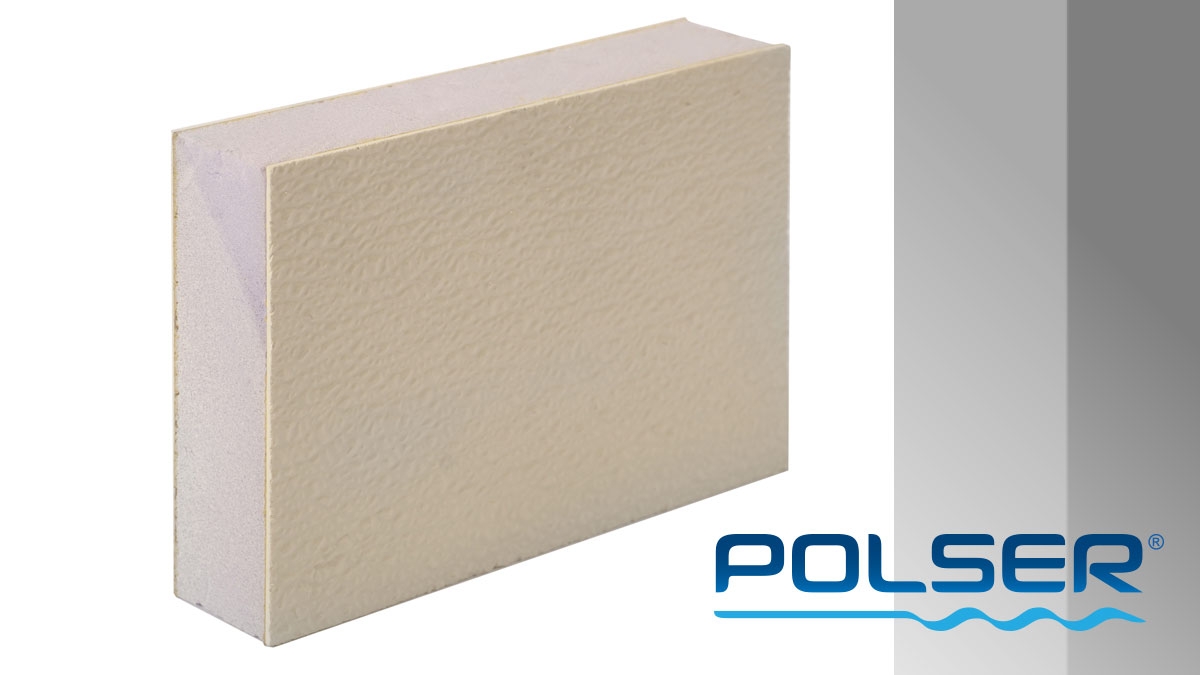

Sandwich panels and sheets (sometimes referred to as composite panels or structural insulation panels) consist of two layers of hard material attached to both sides of a light core. These three components, which are themselves composite, act together as a single composite. The combination of the properties of each component gives a better performance than is possible if they act alone.

The light core keeps the two hard faces in the correct position. The inner structure resists the shear forces and provides insulation, while the two sides provide hard surface air and impact resistance, while protecting the inside of the plane against forces in tension and compression.

Many of the sandwich panel systems include joints between the panels, fixings (usually hidden) and a support system.

Sandwich Panels and Sheets, History and Development

The use of sandwich panels and plates is based on very old times throughout history. In the modern sense sandwich panels are used as composite coating systems, especially since the first invention of these tools for the production of vehicles such as trains and aircraft.

However, the development of advanced sandwich panels for the building of buildings was first used by the architects of the 1930s. After the Second World War they became increasingly popular.

Modern sandwich panels can be combined in straight, twisted, curved, corrugated or almost unlimited configurations. They are produced in a variety of colors, surfaces, thicknesses, edge details and profiles depending on performance requirements.

Sandwich panels and sheets are generally produced outside the construction and pitches to be used. They move from the production site to the construction site. When the parts are combined, they provide a high performance coating with structural strength, high insulation and low weight.

Glass Fiber Reinforced Plastic Sandwich Panels and Sheets

The introduction of sandwich panels in the modern world, though with the metal surface sandwich panels, the use of fiberglass changed everything. A new facade that has many advantages with the use of fiberglass (or glass reinforced plastic, GRP) on the outer surface has brought the roofing material to the architects.

FRP sandwich panels and sheets are a well-designed, high gloss glass fiber composite if desired.

It has become the most popular sandwich panel and plate choice for a wide range of manufacturers and users in a large number of industries and industries.

Fiber-technology GRP panels consisting of thermoset polyester resin and woven roving glass fiber provide superior strength and durability advantage against any other type of metal and laminated product.

You can choose from many thicknesses in the core of GRP Sandwich Panels. Production can be made in any desired size and width.

Fiberglass sandwich panels with advantages over aluminum and galvanized sheet metal exterior coating are more and more widely used.

The clear advantages of FRP sandwich panels are as follows;

• Cost-effective• The desired color option can be applied to all external materials except the whole surface painting at the production stage

• Production in every thickness

• Seamless, production of larger surfaces

• Easy maintenance

• Heat resistance

• Corrosion resistance and non-rusting

• 99.9% antimicrobial surface hygiene with Polser AMB

Generally, building types with sandwich panels are

• Industrial buildings and processing facilities

• Factory buildings

• Temporary buildings

• Storage buildings

• Clean rooms

• Hygiene rooms

• Agricultural structures

•Shopping malls

• Sports facilities

• Transportation buildings

• Automotive sector applications such as truck, truck trailer construction, caravan coatings

Sandwich panels are preferred due to:

• Ease of installation and installation speed

• Stiffness

• Heat, fire and sound insulation

• Air tightness

• Durability and durability

• Low maintenance / cleaning requirements

• Low capital cost

• Low lifetime costs

• Chemical and biological resistance

• Structural light material need

• Resistance to weather conditions

• Equivalence

• Producer firms can find standard products in continuous stock

The point to be taken into consideration in the sandwich panels is that the fire criteria are fully met.

Polser Inc. Fire-resistant panels that meet the expectations can be produced with Firepan applications.

Polser production sandwich panels with glass fiber reinforced plastic (FRP) outer surface offer the most economical composite solutions for modern structural elements.